By Heather Blumenthal

Over the past four years, 20 people have participated in a unique partnership between the Ottawa Hospital’s Biotherapeutics Manufacturing Centre (BMC) and Ottawa’s Algonquin College that provides hands-on training to create the highly qualified personnel (HQP) needed to support the BMC’s important work. That partnership, known as the Canadian Partnership in Immunotherapy Manufacturing Excellence or CanPRIME has been so successful – with all 15 graduates employed in the field, nine of them currently or previously at BMC and the fourth group of five on its way – that it is now being expanded nationwide.

“As a student finishing their studies, preparing to enter the professional world was a daunting task,” says Reuben Benedict, who was among the first to participate in the original CanPRIME program. “With partnerships like CanPRIME bridging the gap, those dream jobs in biomanufacturing that I’ve heard about suddenly became more real than ever.”

“It’s been a very successful approach to training the highly qualified people we need at the facility,” says Dr. Jennifer Quizi, Director of Biotherapeutics Manufacturing Operations at BioCanRx and Director of the Virus Manufacturing Program at BMC. “It’s been so successful that BioCanRx is expanding it to the national level.”

This expansion will result in a standardized biomanufacturing curriculum at six sites across the country: Victoria, Edmonton, Saskatoon, Winnipeg, Toronto and Ottawa. In each case, the program is partnering with an area college and university to implement the curriculum at each of its training sites. CanPRIME students will gain sought-after, hands- on experience in a Good Manufacturing Practices (GMP) biomanufacturing environment. Here, they will learn what is involved in making complex biologic, or ‘living therapies’ like therapeutic cell and virus products that are safe to be used in clinical trials.

Beyond its national expansion, says Dr. Quizi, the program is designed to provide transferrable skills.

“Each facility is different, making something different,” she says. “The standardized curriculum is agnostic to what product is actually made and instead focuses on the key skills, behaviours and competencies required to be successful working in a biomanufacturing environment. We are developing a pipeline of people, training the next generation of HQP, who will be able to work in any GMP environment.”

The program exists thanks to a joint investment of $2.2 million by BioCanRx and Mitacs, a not-for-profit organization the fosters growth and innovation in Canada by solving business challenges with research solutions.

Over the program’s five-year lifespan, it will train more than 70 students, providing each with paid eight-month internships at the biomanufacturing facilities.

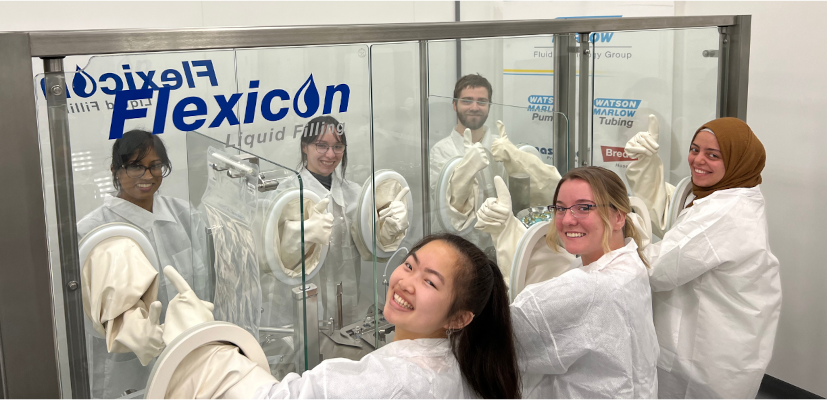

In addition to the training they receive at their home institutions, program participants will also benefit from external training opportunities, such as those offered by CASTL, the Canadian Alliance for Skills and Training in Life Sciences. In late October, the fourth cohort of CanPRIME students at BMC were the first ever to travel to Charlottetown, PEI, for a week of training in bioprocessing at this brand-new facility.

“The students were very excited to travel and participate in this training opportunity at CASTL. CASTL’s new training facility and customizable programming allowed the CanPRIME interns to supplement the knowledge they have gained so far in their placement at the BMC in a safe and de-risked environment, and to learn about and manipulate relevant, bioprocessing equipment that they would not have otherwise had a chance to work with,” says Dr. Quizi. “The CASTL trainers were incredibly knowledgeable and went the extra mile to provide a personalized training program for us- it was a great experience.”

“This experience at CASTL made a great co-op placement even better,” says Salma Alhalawani, a third-year biotechnology intern at Algonquin College and current CanPRIME student. “It is not common to get to travel and receive outside training as an intern. I learned a lot from my week of training at CASTL that I know I will be able to apply at the BMC.”

“CASTL was thrilled to welcome students from the CanPRIME program for a full week of lectures and labs at our new Charlottetown Biomanufacturing Training Facility. Students engaged in intensive hands-on learning in upstream and downstream processes and explored single use technologies. Teaching the next generation of biomanufacturing experts is an integral part of CASTL’s vision,” said Penny Walsh McGuire, CASTL Executive Director. “CASTL is proud to partner with CanPRIME and looks forward to training with future cohorts”.

Sites taking part in CanPRIME 2.0 will begin opening in January 2023. It’s not a small undertaking, says Dr. Quizi, to get these additional training sites open. But the need is evident, and the benefit is obvious and so we are committed and excited to be able to provide these opportunities to more students across Canada.

Heather Blumenthal has been writing about health and health research for more than 20 years and never loses her fascination with the advances Canadian researchers are making.